High purity of the sheet is required for nuclear and other applications, where corrosion of metals is of critical concern. When boric acid or its salt is dispersed into exfoliated graphite, the tensile strength of the molded sheet increases by 50–80%, although it becomes somewhat brittle. įlexible graphite sheets can also be strengthened by the addition of inorganic salts, which had to be uniformly distributed in graphite sheets. Dependences of σ of flexible graphite sheet on the size of starting natural graphite flakes and exfoliation volume of exfoliated graphite. The increase in screen aperture size results in a tensile strength increase through a relationship between exfoliation volume and flake size. 3.64b, the tensile strength of sheets also depends on exfoliation volume of graphite used. 3.64a shows a linear relationship between tensile strength and flake size. The flake size, which is often controlled by screen aperture size, affects the exfoliation volume and, as a consequence, the tensile strength of the resultant graphite sheet. Tensile strain to failure is also reduced by the presence of impurities. Therefore, ash content has to be low in order to achieve high strength by densification of graphite sheets. 3.63b shows that the value of dσ/d ρ is inversely related to ash content. The slope of tensile strength σ versus bulk density ρ, dσ/d ρ, is a measure of the ability of the graphite sheet to be strengthened by densification. At a given density, tensile strength decreases with increasing ash content. Almost the same relationship has been reported. It depends on flake size of starting natural graphite, ash content and exfoliation volume of exfoliated graphite, as well as bulk density of the sheet, and increases approximately linearly with bulk density, as shown in Fig. The typical tensile strength of flexible graphite sheets varies from 4.8 to 6.9 MPa along the sheet.

MATERIAL SAFETY DATA SHEET PAINNT SKIN

1,2,4,5-Tetraaminobenzene tetrahydrochloride and 2,6-Dicarboxypyridine cause skin irritation and serious eye irritation.įor most of the compounds no data are reported for basic properties, such as odor threshold, flash point, explosive limits, decomposition temperature, etc. 3,3′-Diaminobenzidine has carcinogenicity for the rat and is tumorigenic. For example, 3,3′,4,4′-biphenyltetramine tetrahydrochloride is suspected of causing genetic defects and may cause cancer. On the other hand, some of the monomers are potentially dangerous. Inhalation studies with rats using specially prepared fine PBI particles produced no adverse effects. Toxicological testing has shown PBI polymer to be essentially innocuous. There is no indication this product causes any adverse impact on the environment. The product poses few or no unusual hazards in an emergency situation.

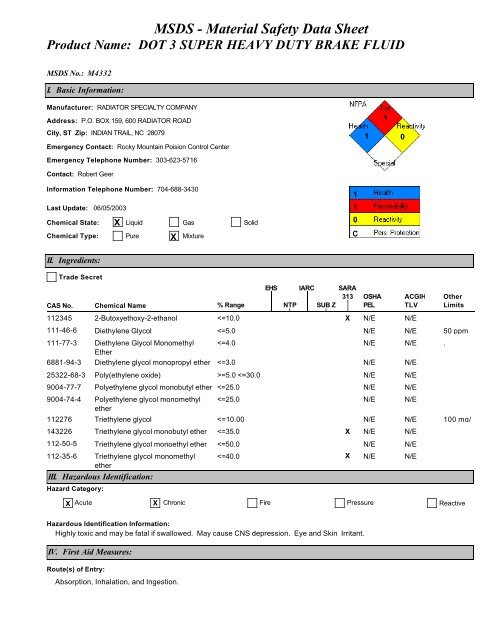

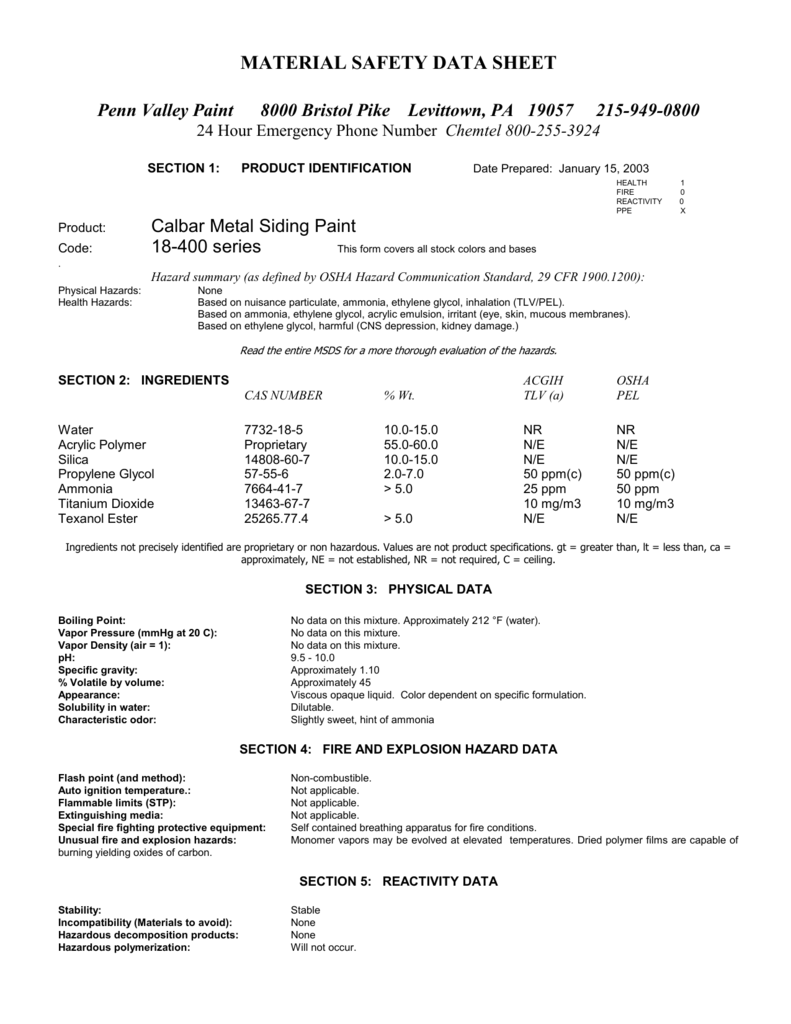

Material safety data sheets for PBI are available from the manufacturer, e.g. Johannes Karl Fink, in High Performance Polymers (Second Edition), 2014 16.6 Safety

0 kommentar(er)

0 kommentar(er)